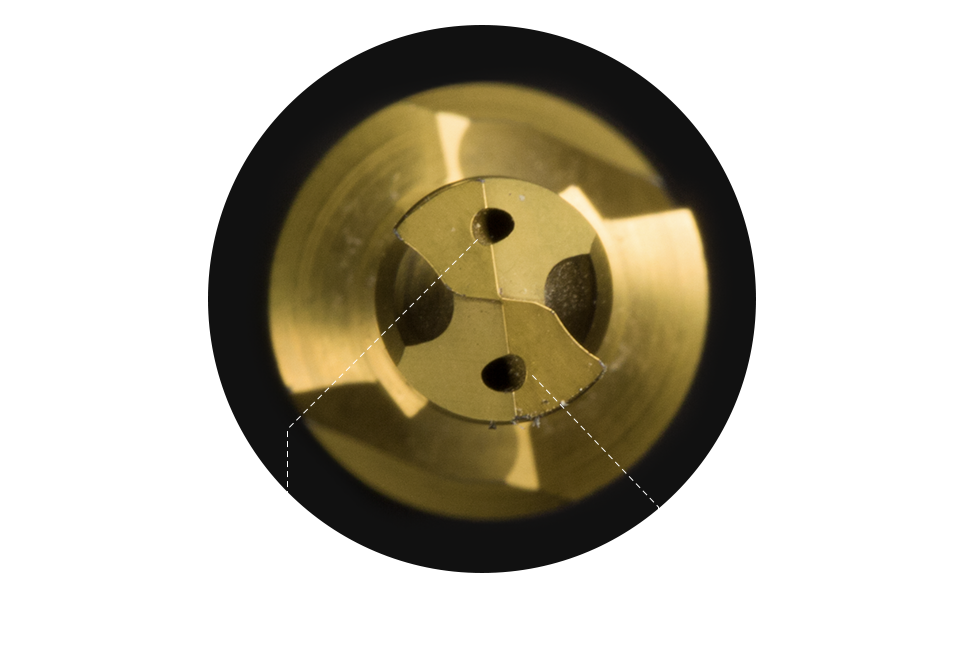

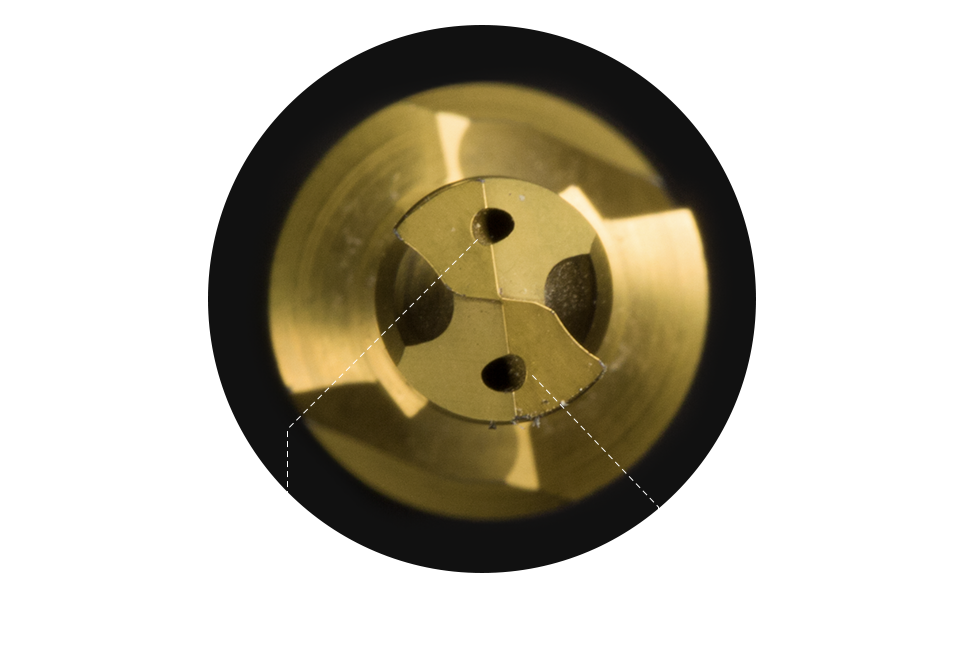

Through coolant holes

An essential feature of all Step Drills we produce, Through Coolant Holes help to regulate tool temperature, as well as providing additional swarf removal properties.

At A&S Tooling, we love taking on innovative challenges for our clients, and that’s exactly what we’ve been up to this month...

To design and manufacture a tungsten carbide cutting tool in order to machine a very accurate ‘O’ ring slot in a tough stainless steel material.

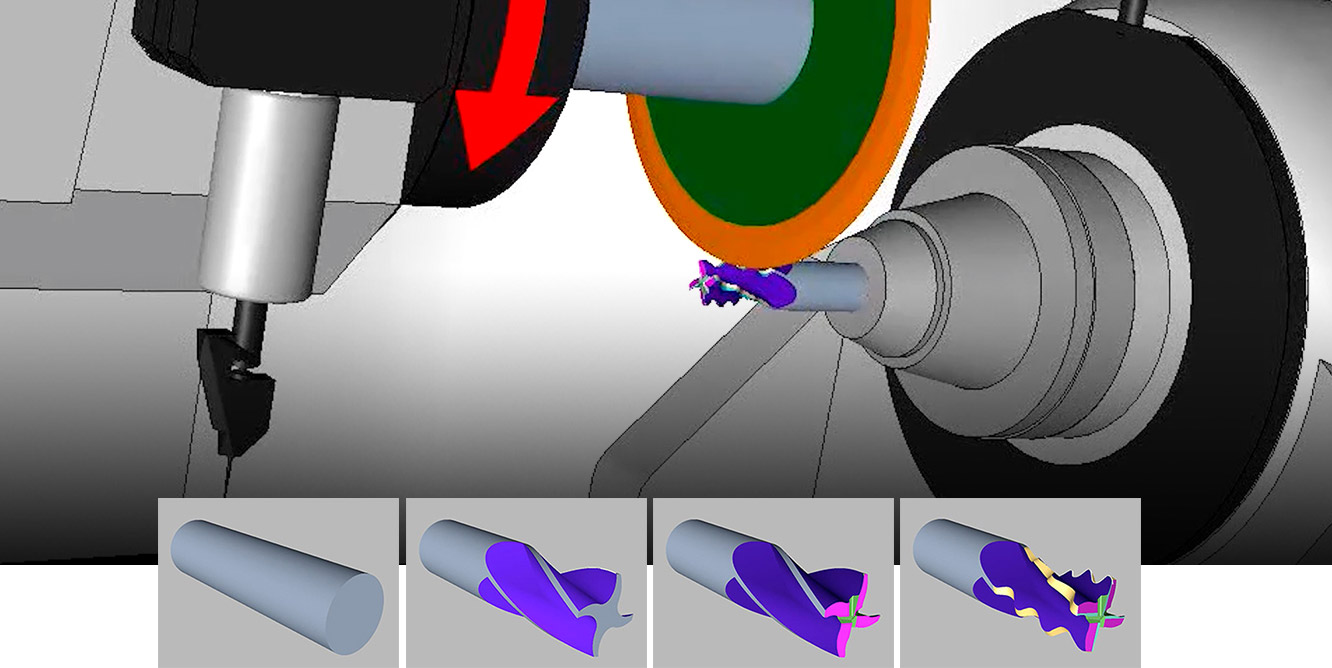

Undoubtedly the biggest challenge was the toughness of the material being machined. Taking this into account when designing, we concluded that the form of the tool had to be linked with a helical flute due. Ultimately this not only helped with surface finish, but gave our client exceptional tool life with the accompanying TiSiN coating we applied.

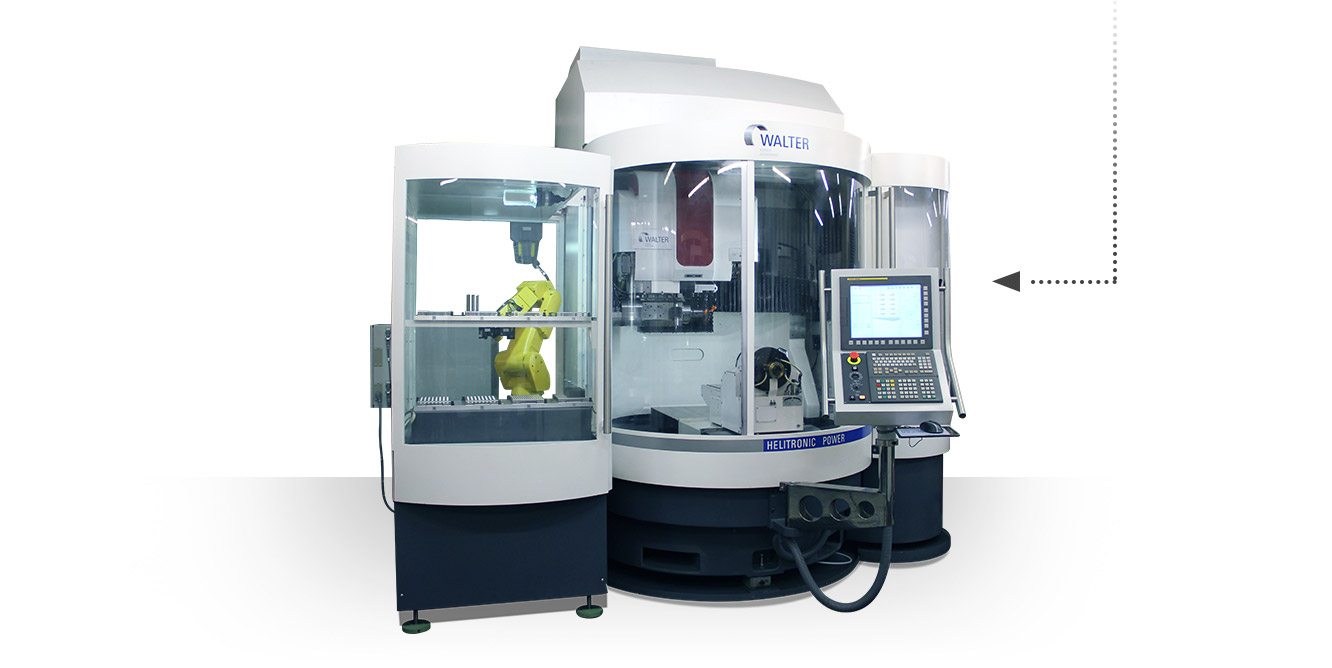

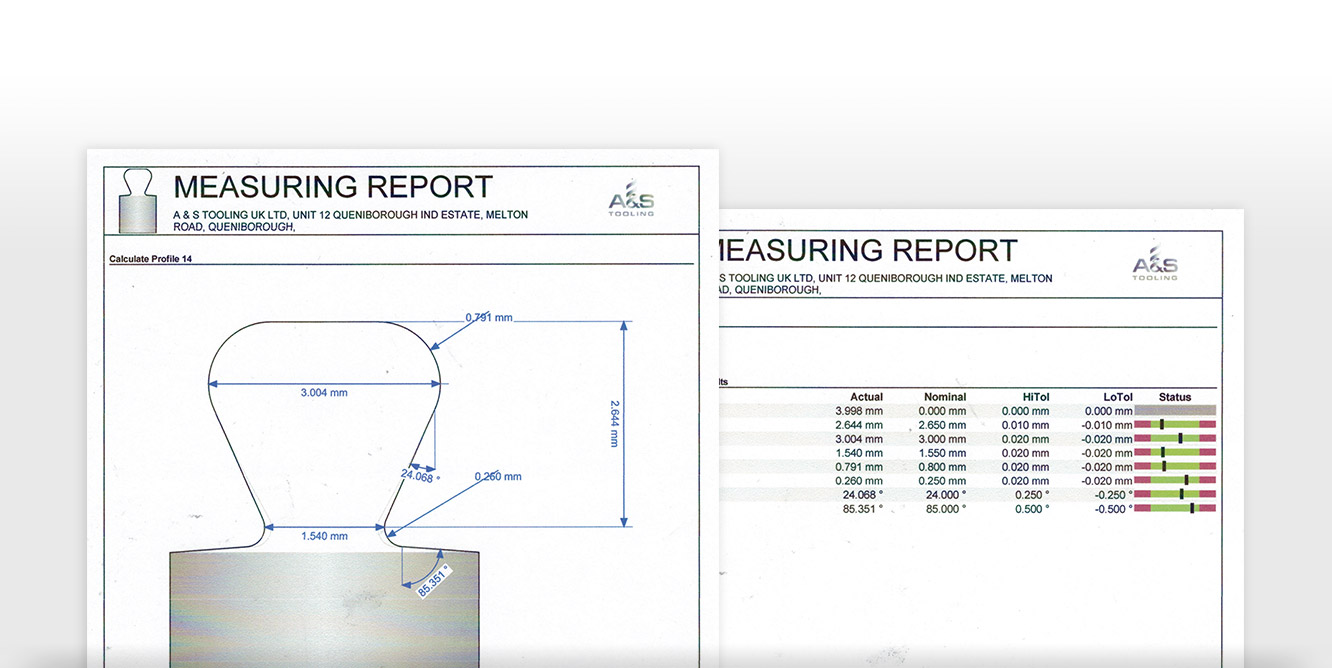

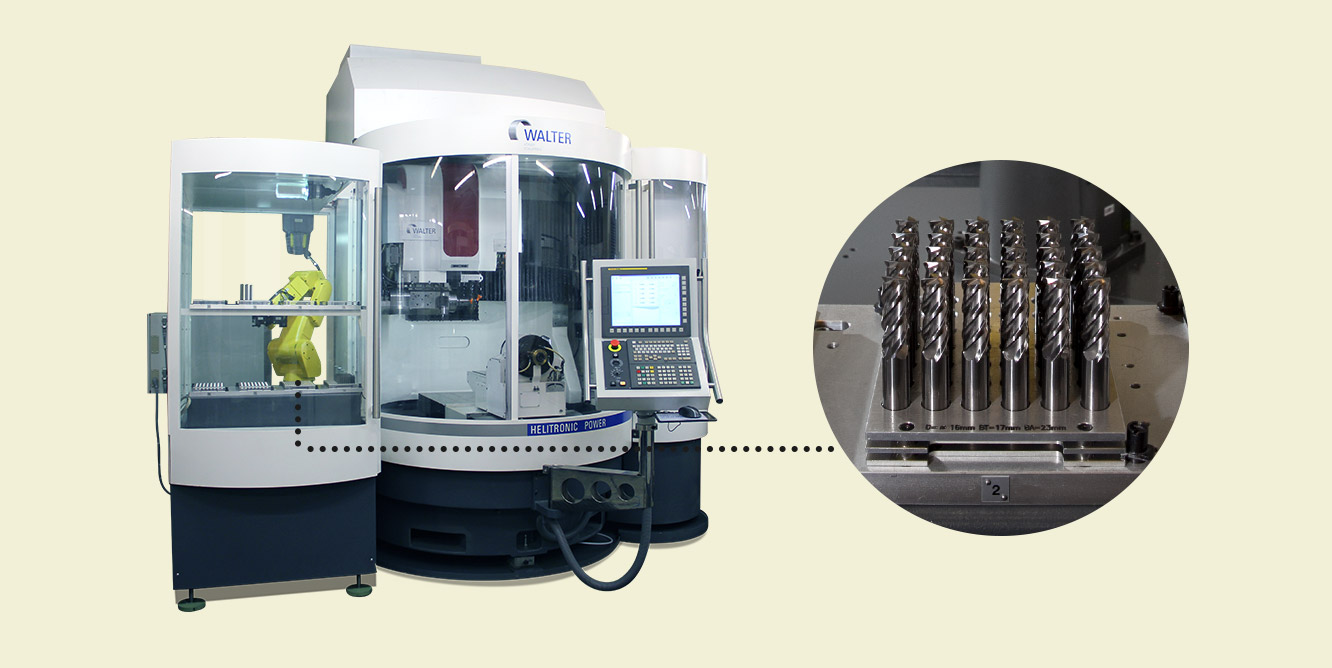

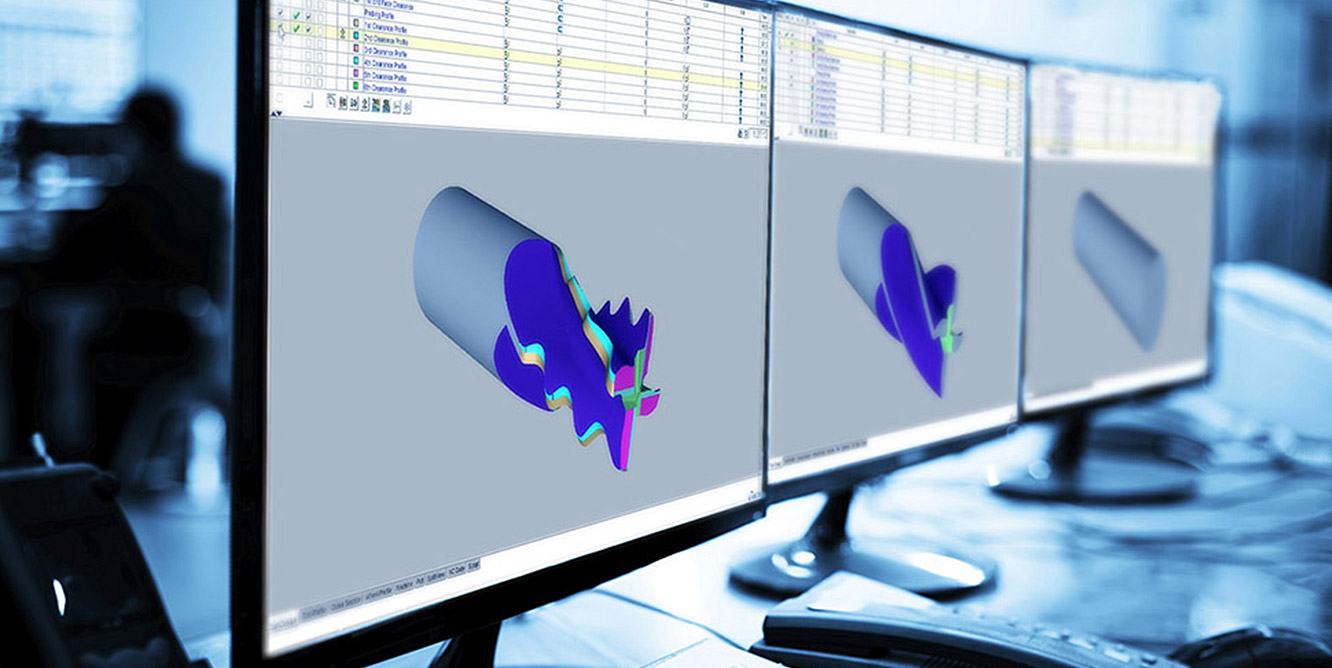

In order to achieve the tight tolerances required on the form, we used our latest CNC 5 Axis tool and cutter grinders in conjunction with our latest measuring machine. As the two machines use the same software, this enables continual in process adjustments to be made.

Each tool was then laser-etched and supplied with its own measuring report – this is to guarantee accuracy and to give customer confidence and peace of mind that they are attaining the desired feature on their component.

At A&S Tooling, we have a team of talented engineers with more than 30 years of experience. Got an innovative challenge for us? Please call us today on 0116 2640 100 or send us your enquiry.

Concerns about the environment and the damage we are doing to our planet are in the news almost daily. There is an increasing pressure on all of us to respond to these environmental issues and protect the Earth for future generations.

Sustainability is (or should be) a board room issue as companies begin to embrace their environmental obligations. Many businesses are working towards, or have already achieved, compliance to Environmental Certification schemes. This kind of corporate social responsibility not only helps protect the environment, it is also commercially advantageous in that it adds a positive, relevant message to your brand. It tells your customers that you care.

Regrinding your worn tools offers multiple benefits. Protecting our environment by saving valuable and finite virgin resources is a compelling one. But it’s not the only one...

Regrinding can reduce tooling costs by up to 50%. The total amount of saving depends on various factors, including the cost of the new tools, the volume and the condition of the existing tools.

We can calculate your saving for you. Just click the button to request a cost saving prediction:

A worn, dull tool is not accurate. The high-end regrinding technology that we use means that we can precisely and reliably match the original manufacturer’s geometry for maximum effectiveness.

Here at A&S Tooling we are experts at what we do. We’d love to help protect and preserve your valued tools, save you money, and help you to minimise your impact on the environment. Please call us today on 0116 2640 100 or send us your enquiry.

We understand that every business is different, every need is unique. Sometimes an off-the-shelf tool simply won’t cut it.

What problem can we solve for you?

A&S Tooling provides a bespoke tool creation service, from consultation and design through to development and manufacture. We listen carefully to our customers to understand your needs in order to design a solution to help you solve even the most complex tooling challenges.

How we can solve your problem.

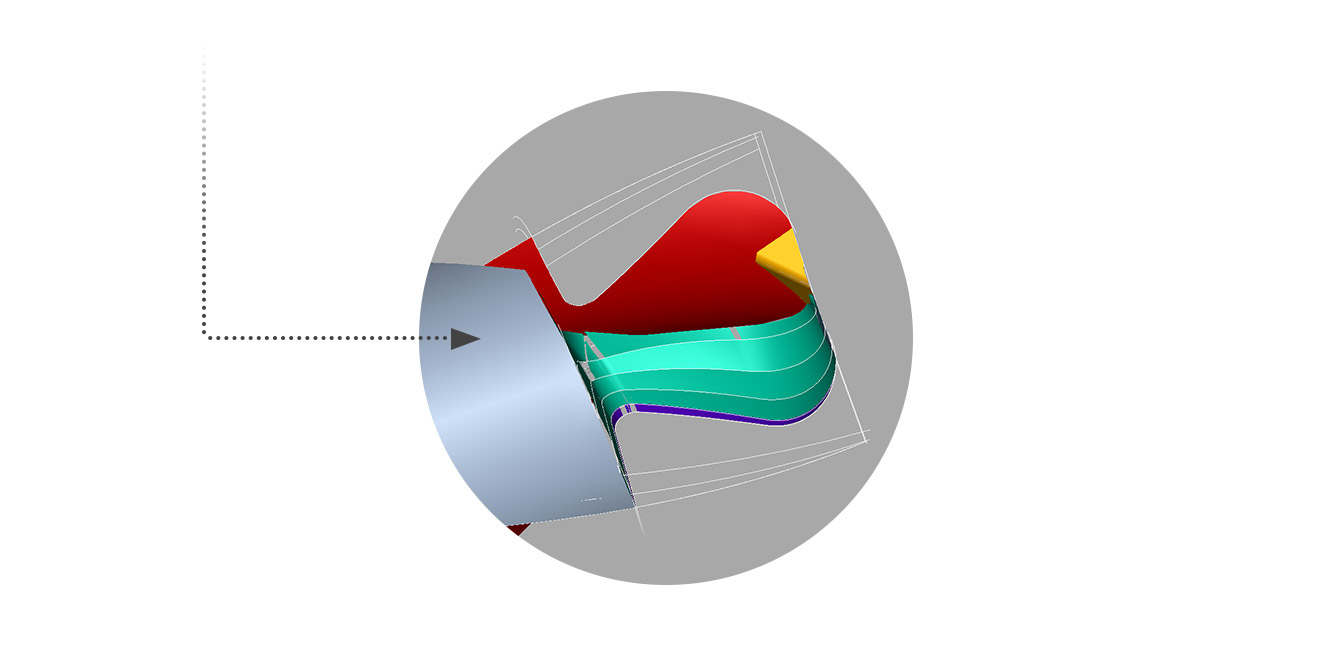

Our experienced and highly skilled team will use their knowledge of materials, machining speeds and tolerances to calculate a precise cutting profile. A detailed drawing will be prepared, then transposed to a full 3D CAD simulation that can be rotated and positioned in a virtual spatial environment for client approval or further refinement.

“Design is not just what it looks like and feels like. Design is how it works.”

Have you been struggling with a tooling problem? Is there something you think ought to be improved, but you’re not sure how? Are you looking for greater efficiency? Give us a call and talk to one of our designers. We are here to help.

To work with a tooling company capable of rising to the challenge, call us on 0116 2640 100 or send us your enquiry.

The automotive manufacturing industry is complex and dynamic, with manufacturing and supply chains spanning the globe and fluxing at the whim of economic climate.

Vehicle manufacturers find themselves having to keep operating costs tight, productivity high and risk low; all whilst maintaining enough inventory to respond when the economy is buoyant and demand increases.

A&S Tooling are part of the automotive supply chain, supplying tooling for a client who manufactures components for automotives. Due to the nature of the industry, the name of the client needs to remain confidential, however their story will resonate with other manufacturers, so whilst we can’t reveal their name, we can explain how we help them streamline their costs as well as optimising performance.

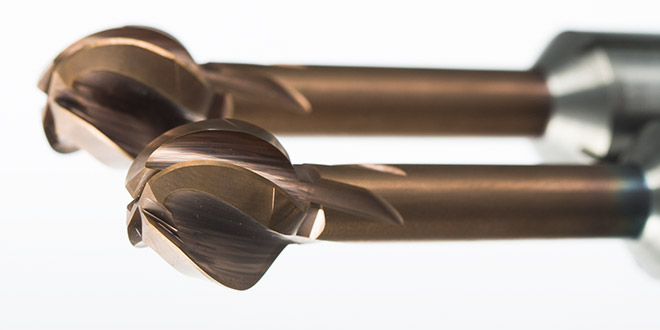

Due to the repetitive nature of the component manufacturing process, the client requires exceedingly high volumes of a particular, standard Flute Endmill.

The automotive industry demands, of course, precision tooling. Quality is paramount, quantity is required, inventories need to be balanced, prices controlled and turnaround times must meet fluctuating manufacturing demand.

The automotive component manufacturer chose to utilise GT4V tooling, formed from submicron grain solid carbide and featuring a multilayer Nano composite TiSiN.

The GT4V is A&S Tooling’s very own range, providing exceptional performance. The tools are designed to give outstanding results on hard and abrasive components as well as on titanium and exotic alloys.

The client has found that there are multiple benefits of GT4V tooling as well as the increased tool life, the performance is optimised due to minimum tool deflection and an improved surface finish.

They are also delighted because A&S Tooling are so confident of the quality and longevity of the tools, we can offer them a discount on our already cost effective regrinding price, because they don’t need regrinding as often. For further details about our Regrinding Service please click here.

“The GT4V tool is incredibly durable. It lasts 4 times longer than the previous tooling we were using. The net result is that we require far less tools, which is incredibly cost effective and efficient.”

For full information and specifications on our GT4V Range please click the button below:

Working in the aerospace sector, our client demanded exacting precision tools with guaranteed levels of performance. Thanks to the investments we've made at A&S Tooling in our our state-of-the-art CNC technologies, we knew we could deliver.

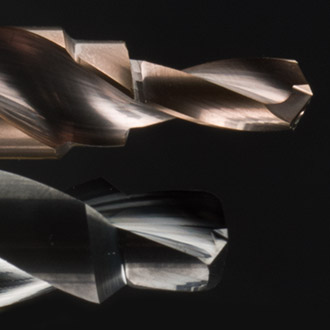

In order to secure the order, we first needed to educate just how competitive we can be as a UK supplier, even compared with overseas suppliers. Knowing that as an aerospace company they use vast numbers of the same tool, this formed the basis for a good match with our fully automated CNC approach, loading trays of tools at a time. Fully believing that their current tools couldn’t be reground, and thinking it’d be more cost-effective to simply buy in new tools, we decided to question this.

Factoring in the sheer quantities of tools required, we costed up based on our 24-7 ‘lights out’ approach, knowing that this would make production viable. As a result, this has enabled our client to reduce their tooling costs for the job by a massive 50% - simply by CNC regrinding of their existing tools. At the same time, our exacting CNC technologies mean that each and every tool that is manufactured, inspected and delivered will be to the same guaranteed standard required by the stringent parameters of the aerospace sector. All of the tools reground and coated were not only returned to that of the original manufacturers geometry, but actually improved as part of the process.

In terms of the all important timescales, their previous supplier generally operated on a 4 week turnaround period. Thanks to our procedures and the capacity of our CNC auto-loading machinery, we instantly cut this down to a 2 week turnaround which included coating. We’ve also tracked usage volumes over time, enabling us to remotely keep on top of stock levels. Ultimately this avoids any possibility of downtime for our client, vital in keeping their aircraft in the skies at all times.

For further details about our 24/7 cutting-edge tool manufacturing services please click the link below:

Designed for repetitive work; the single flute router presents immense durability, maximum chip clearance and a supreme finish.

Manufactured for cutting acrylic and principally designed for their cutting action - which aids in securing the material in place while routing - our single flute routers are ideal for use on handheld and CNC equipment where vacuum or hold down vacuum systems are weak.

Single flute routers are recommended for when the CNC machine feeds too slowly, so can’t keep up with what the spindle is out putting.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. In sapien augue? feugiat at nibh sed, tristique bibendum leo ivamus tincidunt mollis.

Pellentesque ullamcorper nec lorem sed tempus. Curabitur tellus velit, maximus id commodo ac, accumsan sit amet ipsum. Suspendisse orci sem, laoreet id tristique ut, accumsan ut nisl. In hac habitasse platea dictumst. Morbi non libero tristique, laoreet odio ac, maximus eros. Proin id velit convallis, suscipit nibh cursus, ullamcorper erat. Sed volutpat aliquam luctus.

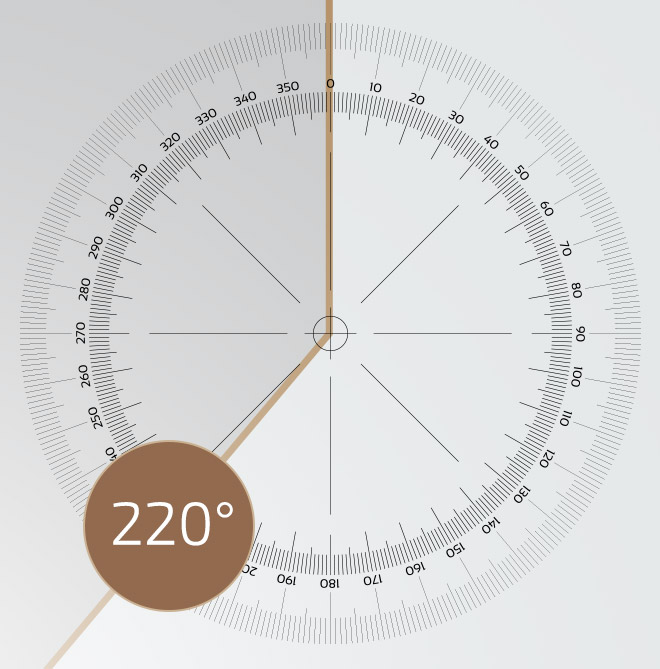

You’re likely to find Lollipop Cutters in your standard tooling catalogue… but they don’t also do what you need them to do. Did you know that our expertly manufactured Lollipop Cutters are able to cut to a 220-degree angle? This is something catalogue versions are not capable of doing.

Experts in Step Diameters, Port Cutters & Drill Reamers.

30 years of experience in producing bespoke Step Drills.

We supply a range of industry sectors, from automotive through to plant machinery. Used as an efficient way of drilling multiple sized holes without the need to frequently change tools, our Step Drills can help you save time and produce cleaner cut holes.

An essential feature of all Step Drills we produce, Through Coolant Holes help to regulate tool temperature, as well as providing additional swarf removal properties.

We are able to offer a full range of Coatings on our Step Drills, extending tool life and performance. Coatings reduce tool wear, friction and the risk of oxidation.

You’ll be among the first to hear the latest news and advice from the team at A&S Tooling.

We promise never to share your details with anyone else or overwhelm you with emails.

Rest assured, we only ever use your data in a way we think you’ll find beneficial. See our privacy policy here.

Home