At A&S Tooling, we love taking on innovative challenges for our clients, and that’s exactly what we’ve been up to this month...

To design and manufacture a tungsten carbide cutting tool in order to machine a very accurate ‘O’ ring slot in a tough stainless steel material.

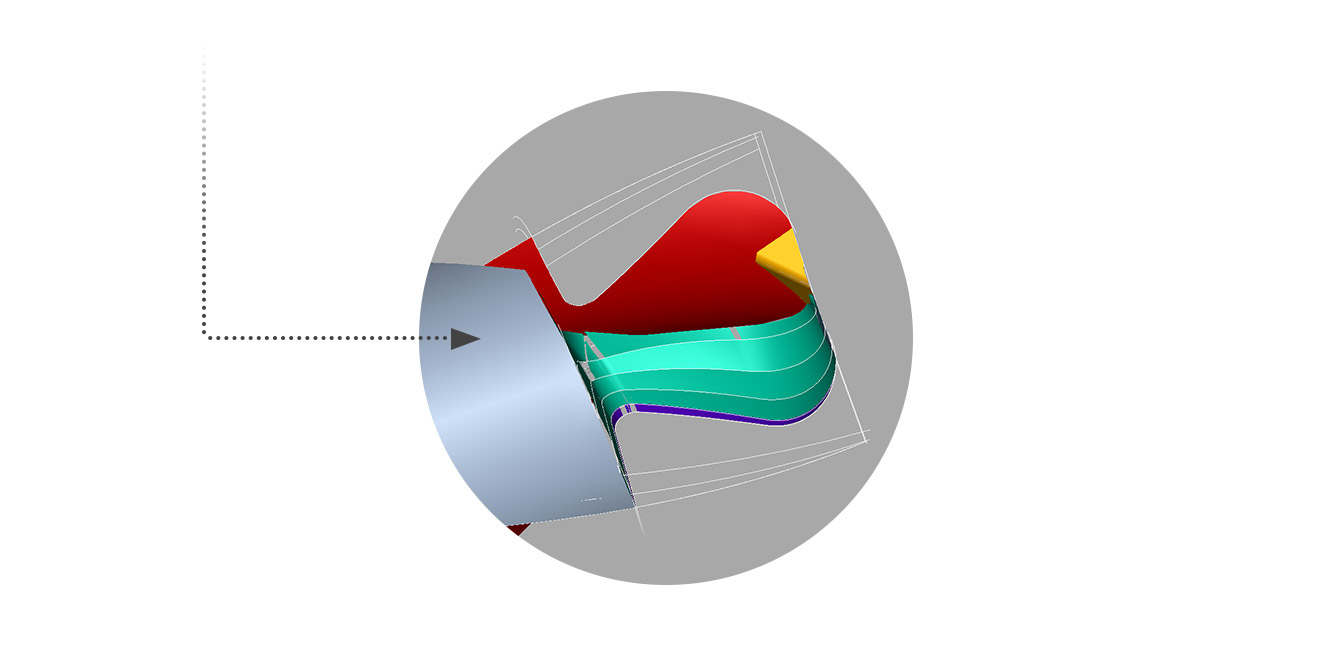

Undoubtedly the biggest challenge was the toughness of the material being machined. Taking this into account when designing, we concluded that the form of the tool had to be linked with a helical flute due. Ultimately this not only helped with surface finish, but gave our client exceptional tool life with the accompanying TiSiN coating we applied.

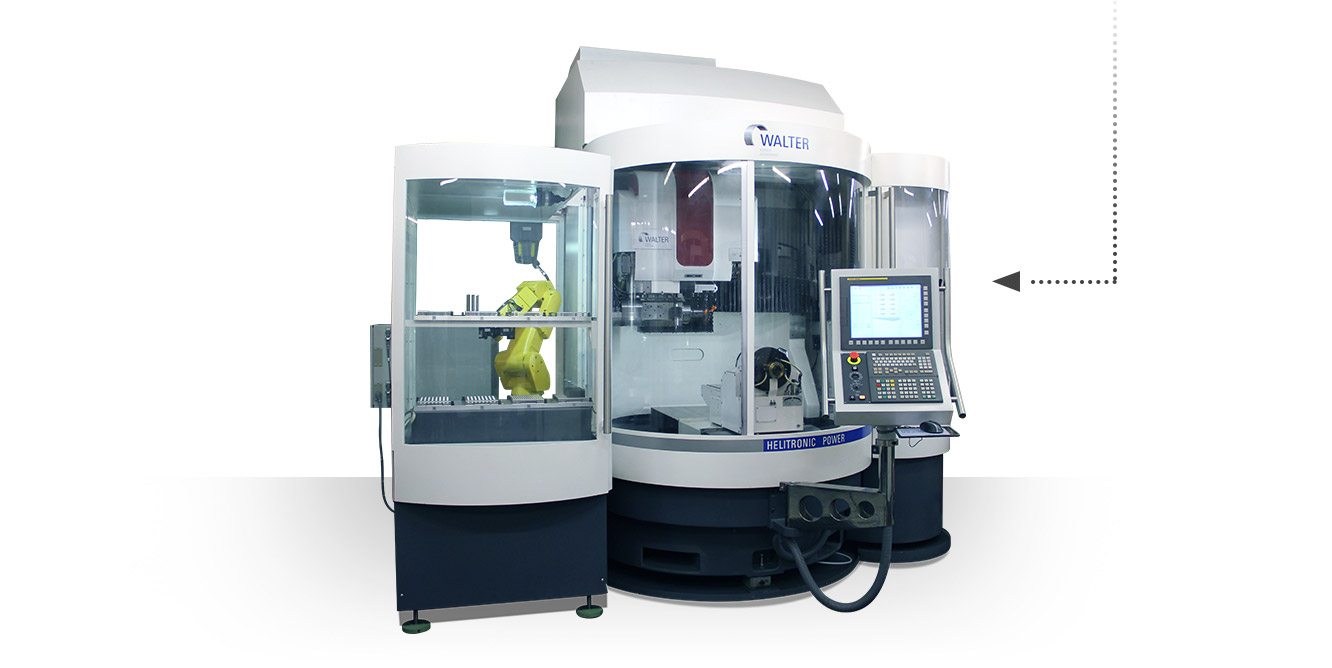

In order to achieve the tight tolerances required on the form, we used our latest CNC 5 Axis tool and cutter grinders in conjunction with our latest measuring machine. As the two machines use the same software, this enables continual in process adjustments to be made.

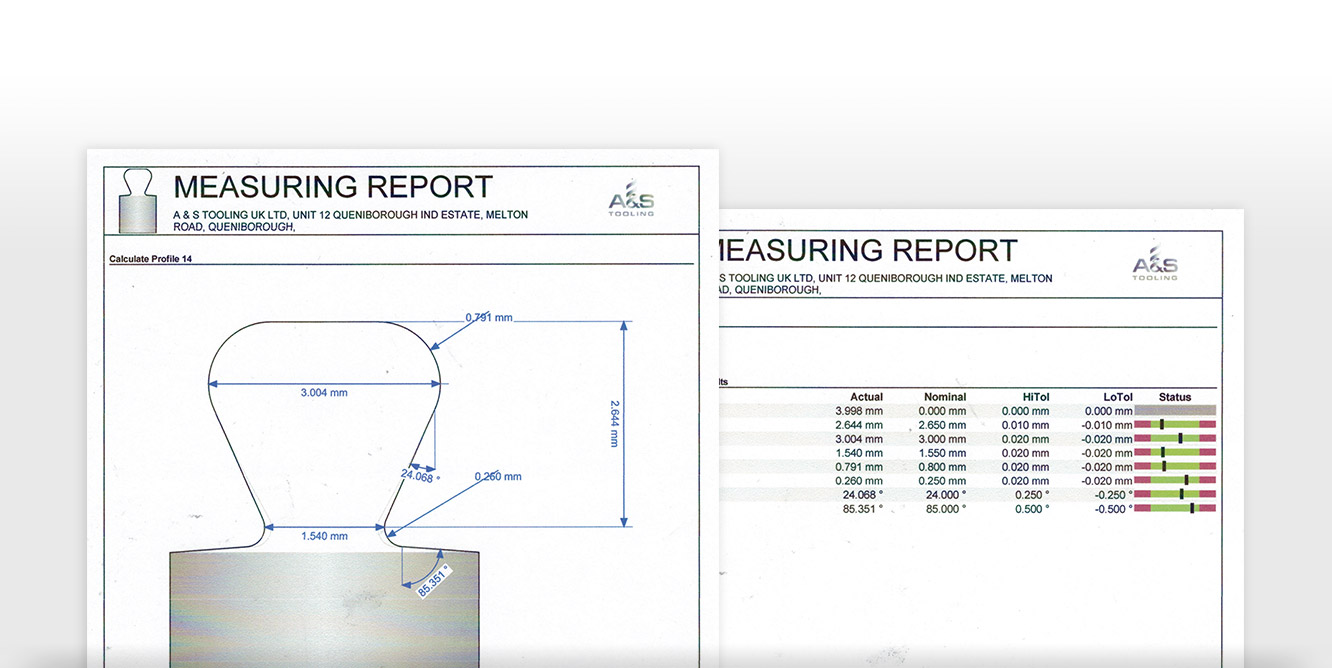

Each tool was then laser-etched and supplied with its own measuring report – this is to guarantee accuracy and to give customer confidence and peace of mind that they are attaining the desired feature on their component.

At A&S Tooling, we have a team of talented engineers with more than 30 years of experience. Got an innovative challenge for us? Please call us today on 0116 2640 100 or send us your enquiry.