Your discount code has been sent directly to your inbox, and is valid until the end of June 2018 on all GT4V orders placed, entitling you to 4 endmills for the price of 3. For example, you may select 4 of any size, with the cheapest tool free of charge. Please allow up to 30 minutes for the email to arrive.

Simply quote your code when placing your order. You can do this by calling us on 0116 2640 100 or by clicking the link below to complete our order/enquiry form:

The discount code is valid until the end of June 2018 on all GT4V orders placed, entitling you to 4 endmills for the price of 3. For example, you may select 4 of any size, with the cheapest tool free of charge. Once you’ve requested your code, we’ll send it directly to your inbox. Please allow up to 30 minutes for the email to arrive. To redeem, simply quote your code when placing your order.

In order to secure the order, we first needed to educate just how competitive we can be as a UK supplier, even compared with overseas suppliers. Knowing that as an aerospace company they use vast numbers of the same tool, this formed the basis for a good match with our fully automated CNC approach, loading trays of tools at a time. Fully believing that their current tools couldn’t be reground, and thinking it’d be more cost-effective to simply buy in new tools, we decided to question this.

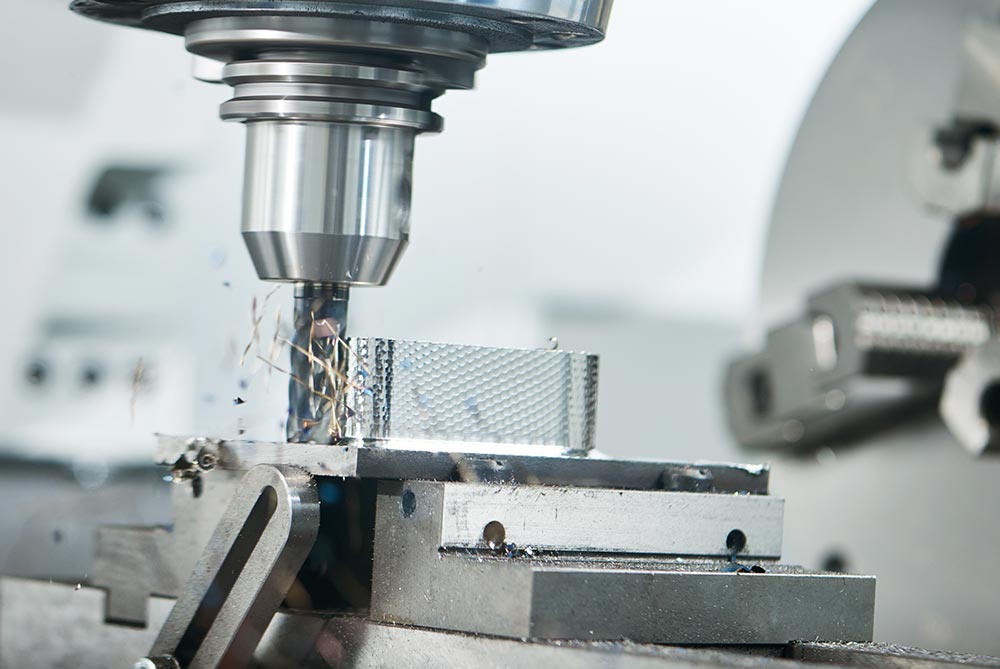

Factoring in the sheer quantities of tools required, we costed up based on our 24-7 ‘lights out’ approach, knowing that this would make production viable. As a result, this has enabled our client to reduce their tooling costs for the job by a massive 50% - simply by CNC regrinding of their existing tools. At the same time, our exacting CNC technologies mean that each and every tool that is manufactured, inspected and delivered will be to the same guaranteed standard required by the stringent parameters of the aerospace sector. All of the tools reground and coated were not only returned to that of the original manufacturers geometry, but actually improved as part of the process.

In terms of the all important timescales, their previous supplier generally operated on a 4 week turnaround period. Thanks to our procedures and the capacity of our CNC auto-loading machinery, we instantly cut this down to a 2 week turnaround which included coating. We’ve also tracked usage volumes over time, enabling us to remotely keep on top of stock levels. Ultimately this avoids any possibility of downtime for our client, vital in keeping their aircraft in the skies at all times.

For further details about our 24/7 cutting-edge tool manufacturing services please click the link below:

Does your production line require replacement tools at a short notice? Our automated service delivers accurate tools for when you need them.

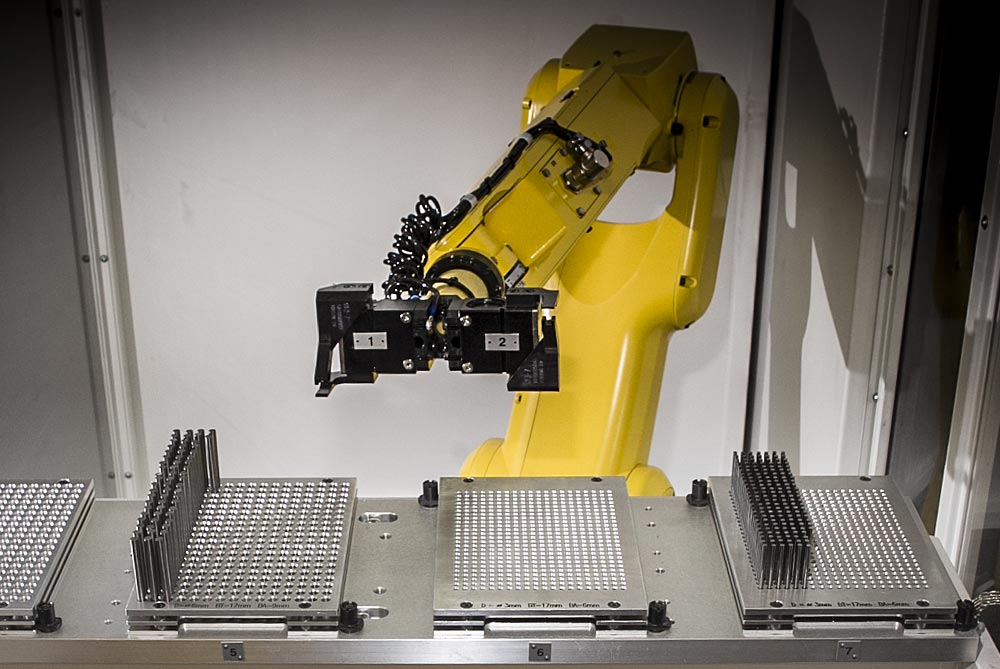

Our fully automated system means we can provide you with exact precision performance tools, 24 hours a day, 7 days a week, catering to your demands and your budget. With our ever-growing variety of innovative facilities, and our passion to take on new technical advances, we have the capacity to meet the most demanding of requirements.

Coming Soon...

Communication, engagement and actions taken through external social media platforms that this website and its owners participate on are custom to the terms and conditions as well as the privacy policies held with each social media platform respectively.

Users are advised to use social media platforms wisely and communicate / engage upon them with due care and caution in regard to their own privacy and personal details. This website nor its owners will ever ask for personal or sensitive information through social media platforms and encourage users wishing to discuss sensitive details to contact them through primary communication channels such as by telephone or email.

This website may use social sharing buttons which help share web content directly from web pages to the social media platform in question. Users are advised before using such social sharing buttons that they do so at their own discretion and note that the social media platform may track and save your request to share a web page respectively through your social media platform account.

This website and its owners through their social media platform accounts may share web links to relevant web pages. By default some social media platforms shorten lengthy urls [web addresses] (this is an example: goo.gl/Y9eEwh).

Users are advised to take caution and good judgement before clicking any shortened urls published on social media platforms by this website and its owners. Despite the best efforts to ensure only genuine urls are published many social media platforms are prone to spam and hacking and therefore this website and its owners cannot be held liable for any damages or implications caused by visiting any shortened links.

The automotive manufacturing industry is complex and dynamic, with manufacturing and supply chains spanning the globe and fluxing at the whim of economic climate.

Vehicle manufacturers find themselves having to keep operating costs tight, productivity high and risk low; all whilst maintaining enough inventory to respond when the economy is buoyant and demand increases.

A&S Tooling are part of the automotive supply chain, supplying tooling for a client who manufactures components for automotives. Due to the nature of the industry, the name of the client needs to remain confidential, however their story will resonate with other manufacturers, so whilst we can’t reveal their name, we can explain how we help them streamline their costs as well as optimising performance.

Due to the repetitive nature of the component manufacturing process, the client requires exceedingly high volumes of a particular, standard Flute Endmill.

The automotive industry demands, of course, precision tooling. Quality is paramount, quantity is required, inventories need to be balanced, prices controlled and turnaround times must meet fluctuating manufacturing demand.

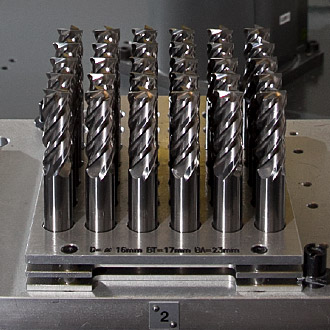

The automotive component manufacturer chose to utilise GT4V tooling, formed from submicron grain solid carbide and featuring a multilayer Nano composite TiSiN.

The GT4V is A&S Tooling’s very own range, providing exceptional performance. The tools are designed to give outstanding results on hard and abrasive components as well as on titanium and exotic alloys.

“The GT4V tool is incredibly durable. It lasts 4 times longer than the previous tooling we were using. The net result is that we require far less tools, which is incredibly cost effective and efficient.” Automotive supply chain client.

The client has found that there are multiple benefits of GT4V tooling as well as the increased tool life, the performance is optimised due to minimum tool deflection and an improved surface finish.

They are also delighted because A&S Tooling are so confident of the quality and longevity of the tools, we can offer them a discount on our already cost effective regrinding price, because they don’t need regrinding as often. For further details about our Regrinding Service please click here.

“Thank you A&S Tooling for the efficient and reliable service.”

For full information and specifications on our GT4V Range please click the button below: