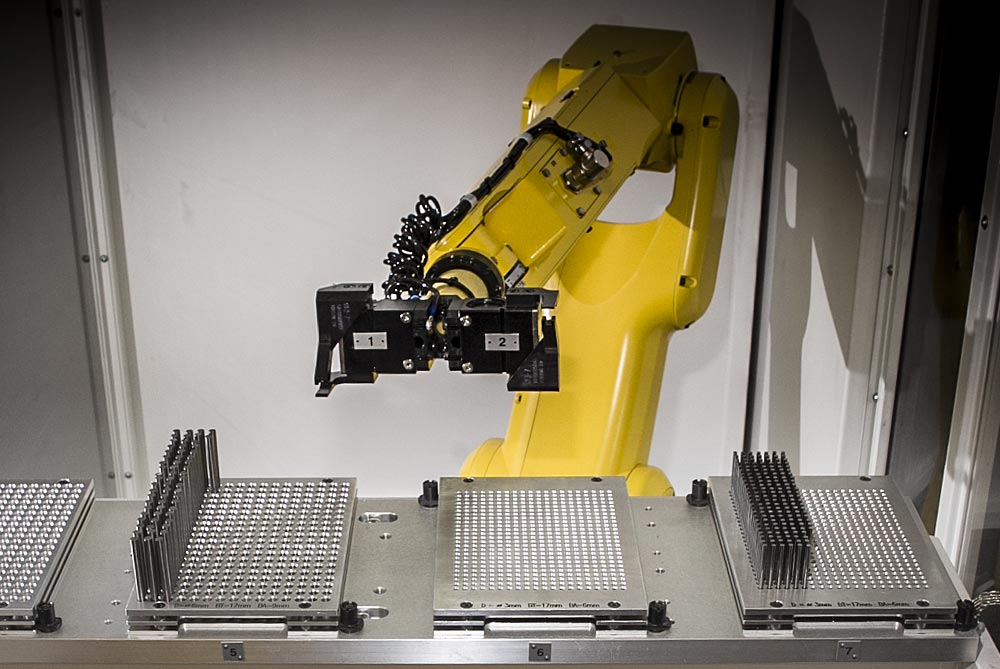

In order to secure the order, we first needed to educate just how competitive we can be as a UK supplier, even compared with overseas suppliers. Knowing that as an aerospace company they use vast numbers of the same tool, this formed the basis for a good match with our fully automated CNC approach, loading trays of tools at a time. Fully believing that their current tools couldn’t be reground, and thinking it’d be more cost-effective to simply buy in new tools, we decided to question this.

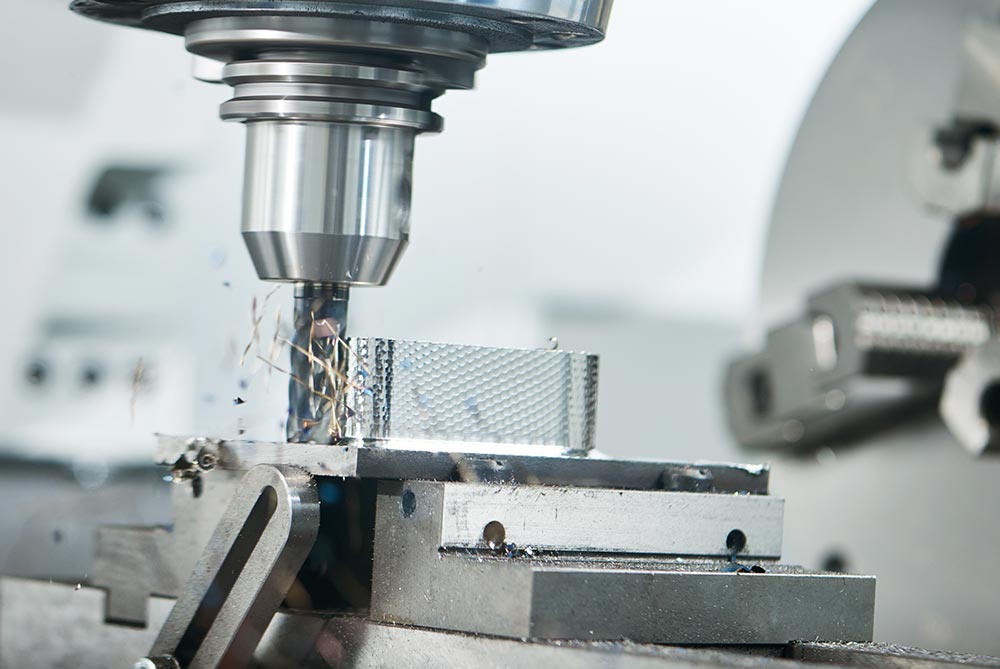

Factoring in the sheer quantities of tools required, we costed up based on our 24-7 ‘lights out’ approach, knowing that this would make production viable. As a result, this has enabled our client to reduce their tooling costs for the job by a massive 50% - simply by CNC regrinding of their existing tools. At the same time, our exacting CNC technologies mean that each and every tool that is manufactured, inspected and delivered will be to the same guaranteed standard required by the stringent parameters of the aerospace sector. All of the tools reground and coated were not only returned to that of the original manufacturers geometry, but actually improved as part of the process.

In terms of the all important timescales, their previous supplier generally operated on a 4 week turnaround period. Thanks to our procedures and the capacity of our CNC auto-loading machinery, we instantly cut this down to a 2 week turnaround which included coating. We’ve also tracked usage volumes over time, enabling us to remotely keep on top of stock levels. Ultimately this avoids any possibility of downtime for our client, vital in keeping their aircraft in the skies at all times.

For further details about our 24/7 cutting-edge tool manufacturing services please click the link below: